EFFLUENT

Gotta keep it Separated!

Being a GEA Dealership gives us the opportunity to source, supply, and install the proven Canadian brand of Houle Effluent Products. Originally designed for barn applications, these products are proving their worth in the Canterbury region and adhere to all Effluent requirements set out by ECAN. We also have the knowledge and know how to design a system to suit your effluent requirements.

HOULE SLOPE SCREENS

GEA Slope Screens

Canadian based company Houle, offers a full range of effluent slope screens.

These screens are one of the few things in the world today that has no moving parts. The screens do a superb job of separating effluent solids from liquid. The screened liquid is then available to be reused for wash down water, or irrigated back onto the farm. Using the screened water for irrigation assists with soil filtration rates allowing pasture to become suitable for grazing faster.

Available in a variety of screen sizes from 4ft through to 8ft dependent on your requirements.

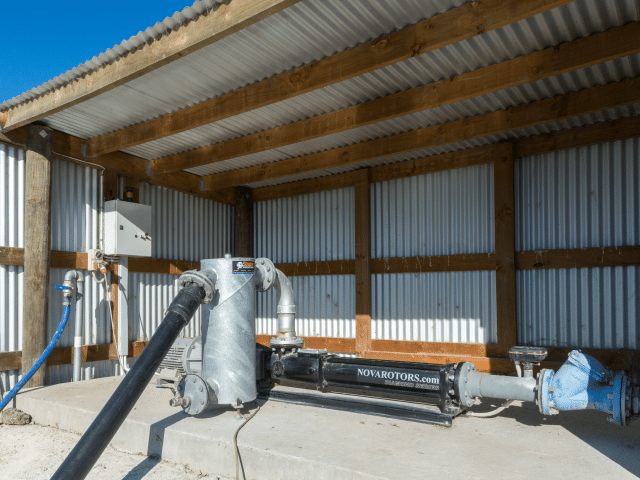

NOVA ROTA EFFLUENT PUMPS

Nova Rota Effluent Pumps

They are self priming, and have a non clogging operation with high suction lift capabilities.

Consisting of a cast iron body, with hard plated stainless steel rotor, and nitrile serrator, and WEG motor with a stainless steel base plate these Italian Pumps are built to last.

YARD FLUSH VALVES

GEA Yard Flush Valves

Another quality robust Canadian built effluent product. This is the no fuss easy way to keep your yard, barn and feed pad clean.

The specially engineered pumps on pontoons and flush valves are designed to discharge flush water in high volumes with supreme cleaning results. The controlled flow distributes evenly across the yard with a 6M working width per valve, with no restriction on time compared with using flush tanks.

Bauer Effluent Equipment

Solids Separators

BAUER Solids Separators set the standard for the removal of solids from farm effluent. Fully automated separation of effluent into liquid and solid factions dramatically improves how the effluent can be stored and handled.

Effluent from a feed pad or dairy shed first passes through a stone trap to remove stones and sand. The effluent then flows into a holding tank. Effluent in the holding tank is mixed to provide a uniform consistency and is then pumped up to the solids separator. Excess effluent is by passed back into the holding tank.

The separator removes the solids from the effluent by means of a stainless steel screw press and screen with a screen size as small as 0.25mm. The moist solids fall into a storage bunker awaiting dispersal. The liquid faction flows to a storage tank or holding pond

The liquid in the storage tank or pond can now be pumped out and distributed by almost any type of spray irrigation system. Due to the small size of any solids that may still remain in the liquid effluent it can be distributed by irrigation systems with small nozzle sizes such as centre pivots and K line irrigation systems.

Bauer Effluent Equipment

Magnum Pumps

The BAUER submersible motor

pumps impresses with singular

performance, versatile application and long lifespan.

THE FACTS

- Conveying capacities up to 250 m3/h

- Outstanding cutting performance

- High quality chrome steel cutting unit

- Submersible rotary motor 4,0 – 15,0 kW

with insulation class H (optional) - Higher flow rate efficiency class IE 2

- Temperature control for application in biogas plants

- Additional security thanks to leakage sensors

- High efficiency, low operating costs